CNC Machining Service

Ecod’s bespoke CNC service is the solution for engineers, product developers and designers who need to prototype and produce small batches.From simple designs to complex designs with tight tolerances, our ISO 9001 certified CNC machine shop ensures excellence.

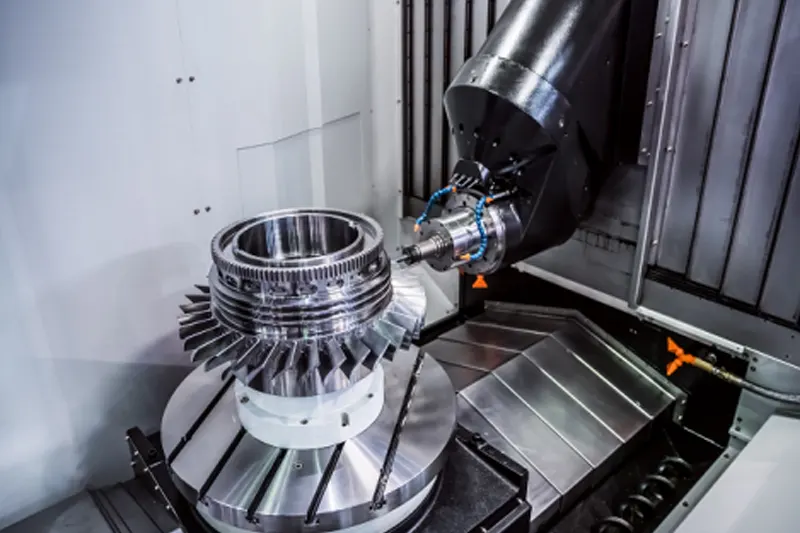

CNC Milling Service

CNC Milling performs multi-axis milling operations including 3, 4 and 5-axis machining processes.Provides precision and allows the creation of detailed and specific geometries from metal or plastic blocks.

CNC Milling Service

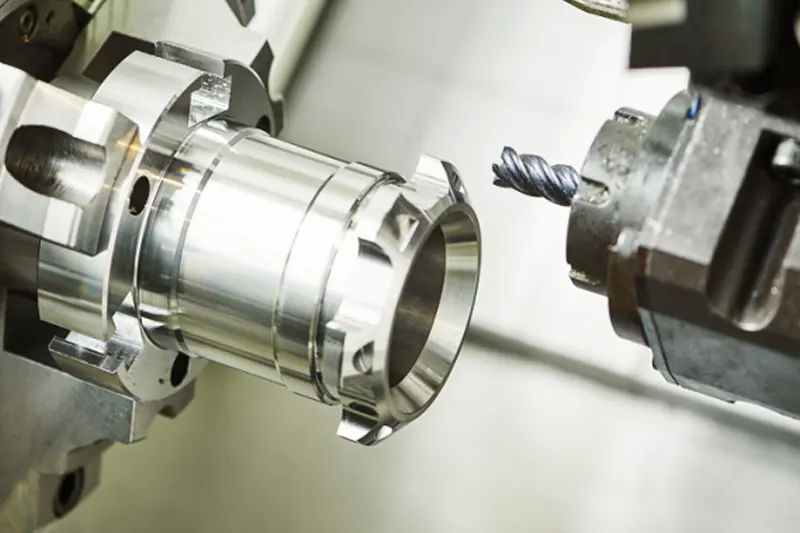

CNC turning uses CNC lathes and turning centres to shape metal bars, primarily for cylindrical parts.It ensures that components achieve consistent dimensions and smooth surfaces.

CNC Machining Tolerances

standard | CNC machining services

| CNC Turning Service

|

Maximum part size | 4000 1500 600 mm 157.559.123.6 in | 200×500 mm 7.919.7 inches |

Minimum part size | 4×4 mm 0.10.1 inch | 2×2 mm 0.0790.079 in |

Minimum feature size | Φ 0.50 mm Φ 0.00197 in | Φ 0.50 mm Φ 0.00197 in |

standard tolerances | Metal: ISO 2768-m Plastic: ISO 2768-c | Metal: ISO 2768-m Plastic: ISO 2768-c |

linear dimension | +/-0.025 mm +/-0.001 in | +/-0.025 mm +/-0.001 in |

aperture (No expansion of holes) | +/-0.025 mm +/-0.001 in | +/-0.025 mm +/-0.001 in |

diameter of axle | +/-0.025 mm +/-0.001 in | +/-0.025 mm +/-0.001 in |

rim condition | The sharp angle will be removed as either a chamfer or a radius. The size or radius of the chamfer must be indicated on the drawing. | |

Threaded and threaded holes | Diameter: Φ 1.5-5mm, Depth: 3 diameter Diameter: Φ 5mm, depth: 4-6 diameter | Diameter: Φ 1.5-5mm, Depth: 3 diameter Diameter: Φ 5mm, depth: 4-6 diameter |

Eco can produce threads of any size and size that the customer requests. | ||

text | Minimum width 0.5 mm, depth 0.1 mm Eco can create standard text using CNC engraving or laser engraving according to the customer’s request. | Eco can use laser marking to create standard text for CNC turning parts. |

delivery time | Within 5 working days | Within 5 working days |

Why choose our CNC Machining Services ?

Consistently high quality

State-of-the-art CNC capabilities, rigorous quality checks, and constant communication ensure that every machined part you receive meets the highest standards of consistency and reliability.

Highly experienced

Our experienced engineers can provide you with the most suitable solution for your part design, material selection, surface finishing and even delivery time.

Rapid delivery

Ecod has a strong manufacturing capability that ensures quick turnaround of CNC machined parts.In addition, with our diverse shipping options, you'll be able to receive your order on time, without the usual hassles.

CNC Machining Service FAQ

CNC processing is widely used in various industries. Are common in aerospace, automotive, consumer electronics, robotics, agriculture, and other areas where metal parts are frequently used. It is also widely used in medical devices, household goods, energy, oil and gas, and other consumer applications. It is one of the most common processing methods in the manufacturing field.

Our CNC services have multiple uses in terms of material compatibility. Commonly used CNC materials include metals such as aluminum, steel, brass and copper, as well as plastics such as ABS, polycarbonate and POM. However, the availability of specific materials may vary, so it is best to contact us directly.

Eocd meets the needs of one-time prototypes and mass production operations. Therefore, there is usually no strict minimum starting order. Whether you need a single part or thousands of parts, Eocd is designed to provide a solution.