Sheet Metal Fabrication Service

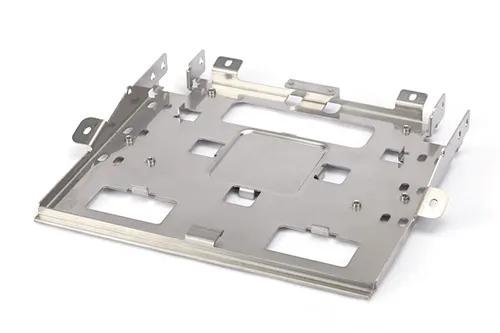

Select Ecod online sheet metal Manufacturing Services to produce custom sheet metal parts through complex small batch prototypes and extensive mass production. You can choose from various materials and manufacturing processes. Our domestic sheet metal manufacturers and a knowledgeable team of engineers ensure that each part is manufactured to precise specifications and quality standards.

laser cutting

Laser cutting is a technology that guides high-power laser cutting of metal sheets that provides precise, fast machining and the ability to create complex designs with smooth surfaces and strict tolerances.

Plasma cutting

The processing principle of plasma cutting machine is the same as that of electric spark processing, that is, electricity melting and cutting the workpiece. The process cuts conductive materials through a hot-plasma-accelerated jet, and is particularly suitable for custom-cutting metal plates up to 6 inches thick.

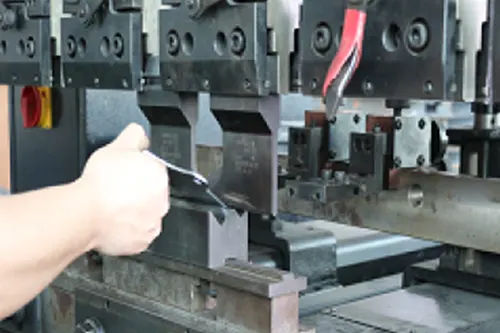

winding

Bending is a multi-purpose sheet metal manufacturing process that forms V-, U-, and channel shapes in materials, providing high accuracy and reproducibility at the lowest setting cost. Perfect for a complex geometry.

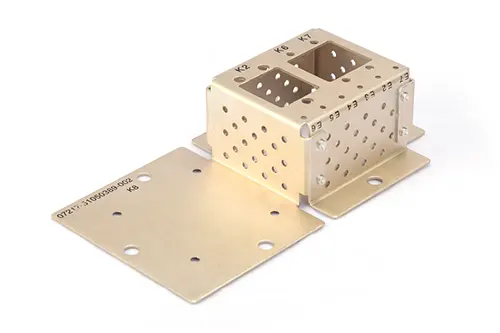

Sheet metal processing materials

Our selection of sheet metal materials includes aluminum, brass, stainless steel and copper, each enhancing the durability and aesthetics of metal parts.

Sheet metal processing tolerance

Feature | Common Difference |

angle head | +/-2 degrees |

offset | +/-0.024 in. (+ / -0.608 mm) |

Bend to edge | +/-0.020 in. (+ / -0.508 mm) |

Bend to the hole / hardware / bend | +/-0.030 in. (+ / -0.762 mm) |

aperture | +/-0.010 in. (+ / -0.254 mm) |

Side to side / hole; hole to hole | +/-0.010 in. (+ / -0.254 mm) |

A trait separated by two or more bends | +/-0.060 in. (+ / -1.524 mm) |

Hardware to the edge / hole | +/-0.020 in. (+ / -0.508 mm) |

Hardware to hardware | +/-0.030 in. (+ / -0.762 mm) |

Sheet Metal Fabrication Service FAQ

Ecod offers a full range of services, including cutting, bending, stamping, welding, and assembly. Our state-of-the-art machinery ensures the precision and high quality completion of all projects.

Ecod is adaptable to small and large production operations, from single prototype to mass production without strict minimum order volume.

The K coefficient is the ratio of the neutral shaft to the material thickness. This value varies with the various physical properties and thickness of the material used.