Surface Treatment Service

Surface Treatment

Our parts finishing service is excellent because our team is expert in plastics, composites and metal surface finishing. Furthermore, we have state-of-the-art machines and infrastructure that can turn your ideas into reality.

Polishing

On metal and hard plastic, our polishing uses efficient machinery to reach our parts between Ra 0.8-Ra 0.1 for a cleaner surface.

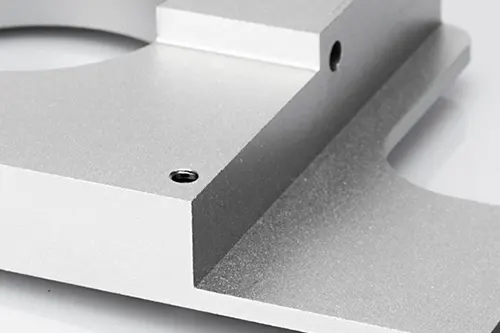

Sand Blast

Our brush coating technique uses sand bands on the material to create different patterns that match the structure and color of the part.

Electroplating

Electroplating reduces the metal cations in the electrolyte solution, creating a metal coating on the metal surface. The process can be used for corrosion resistant and wear resistant purposes, but also for decorative purposes.

Anodic Oxidation

To increase surface hardness and heat dissipation, we use anodized technology to enhance the appearance of the parts and fuse well for spray paint and primer treatment.

Heat Treatment

Usually, heat treatment changes the material properties of the metal, which means increasing the strength and hardness of the metal, allowing it to withstand more extreme applications.

Surface treatment specification

Name | Product Description | Material | Pigment |

Sand Blast | Sandblasting is a process of strong propulsion (usually using high pressure) jet medium stream hitting a surface to remove undesired coatings and surface impurities. | Aluminum, steel, stainless steel, brass, copper | not applicable |

Anodic Oxidation | Our anodizing process keeps our parts corrosion resistant and wear for a long time. It is also an ideal spray paint and primer finish and looks great. | Aluminum materials | Transparent, black, gray, red, blue, and gold |

Electroplating | Plplating coating protects the part surface and reduces metal cations by applying a current to prevent rust and other defects. | Aluminum, steel, stainless steel | Gold, silver, nickel, copper, and brass |

Polishing | Range from Ra 0.8 to Ra 0.1, the polishing process uses grinding materials to rub the part surface to make the gloss less shiny depending on your requirements. | All materials | not applicable |

Surface Treatment Service FAQ

Yes, we provide all surface treatment options, even if these are not available in the list. However, if you do not find a surface treatment option in the list, you can still send us a quote request. Our engineers will consult with you to discuss how we will continue to do so.

The end-user’s application and the type of material determines it. For example, if your parts are used in outdoor environments, galvanized or anodized may be ideal. At the same time, for indoor use, the basic painting is enough. Furthermore, some surface treatment options are only for a particular type of material. For example, anodization is the only case for aluminum and titanium.

Since machining surface finishing is not suitable for all situations, the operating environment can cause surface degradation. In addition, it has a high risk of forming corrosion, and it is not conducive to the appearance.